About PFA Lined Butterfly Valve (Wafer Type)

| High Temperature Low Temperature Medium Temperature |

| By Lever By Gear By Actuator |

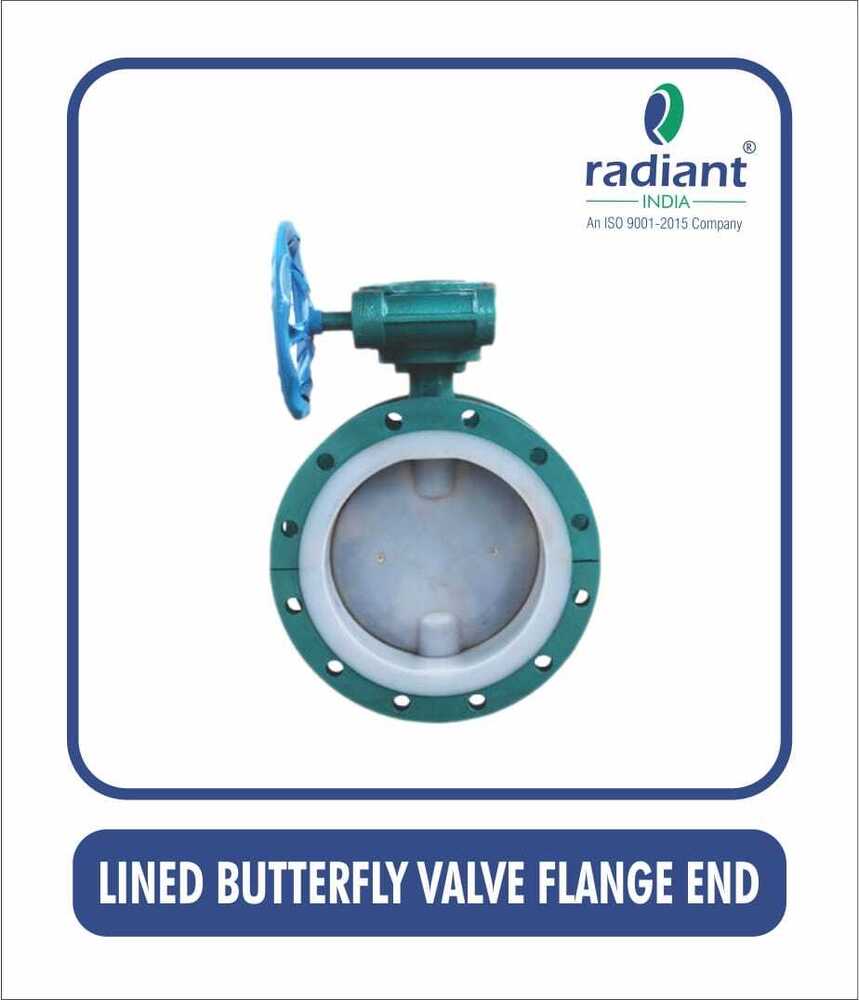

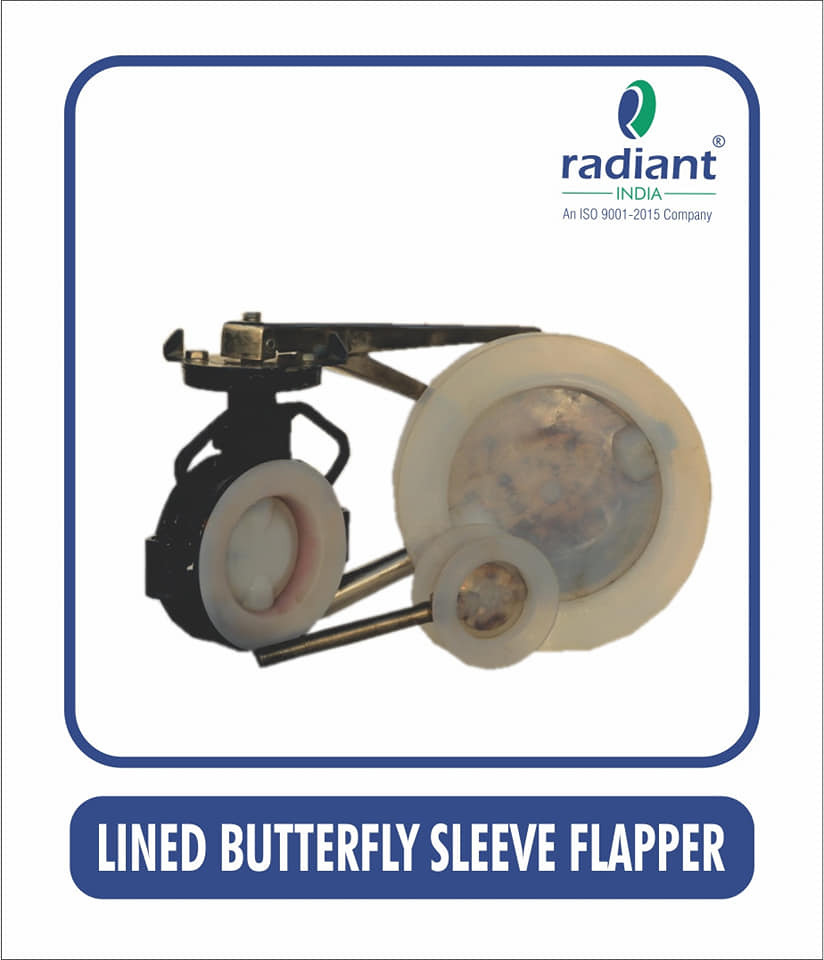

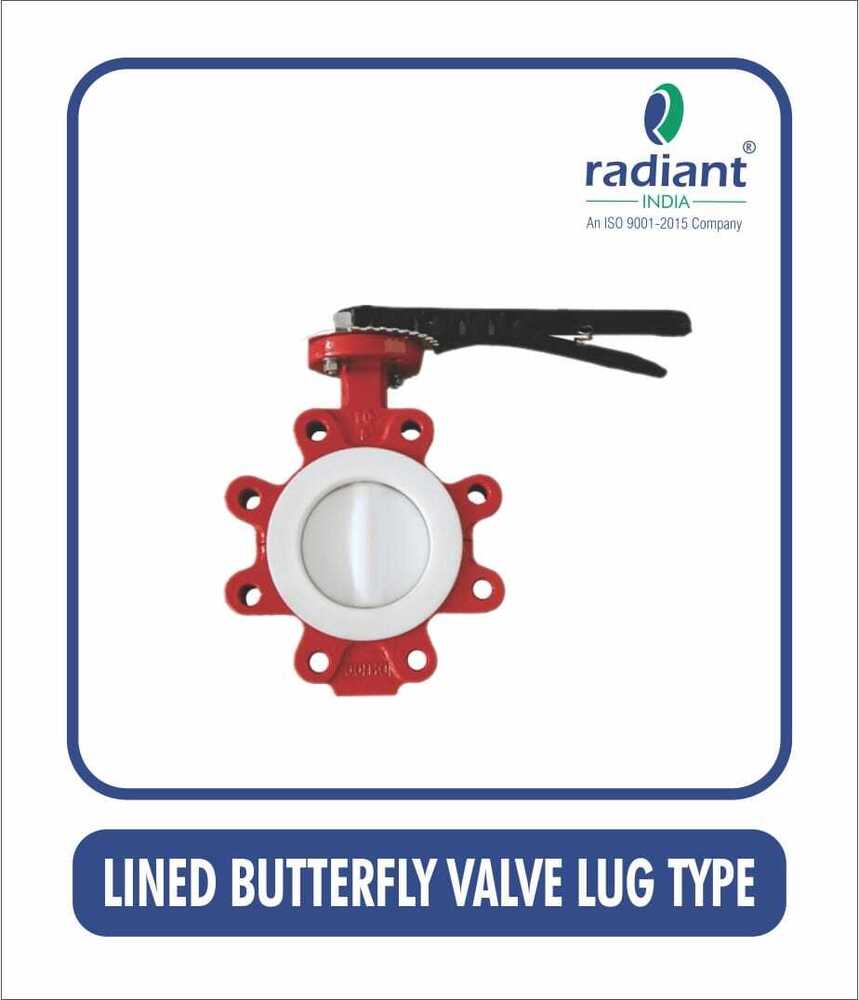

| RADIANTs FEPPFA Lined Butterfly Valves have a continuous discshaft lining and a body lining that extends well beyond the secondary seal area |

| Our offered valves are intricately designed under the vigilance of skilled professionals using quality tested raw material and sophisticated technology in line with the international quality standards |

| ï ï ï ï ïInnovative design |

| ï ï ï ï ïDesign Standard BS EN 5932004 Formerly BS 5351 |

| ï ï ï ï ïDrilling ANSI B165 DIN PN 1016 |

| ï ï ï ï ïLining Thickness 3 to 5 mm |

| ï ï ï ï ïTesting Standard BS EN 1226612 2003 |

Exceptional Corrosion ResistanceEquipped with a full PFA encapsulated disc and seat, this butterfly valve assures maximum protection against corrosive chemicals, acids, and hazardous liquids. The robust anti-corrosion coating extends the product lifespan, making it ideal for demanding industrial environments.

Universal Wafer Type MountingThe wafer-type design allows easy sandwich fitting between ANSI 150#, PN10, or PN16 flanges. Its ISO 5211 direct mount interface accommodates lever, gear, and actuator operations, enhancing flexibility for maintenance and automation processes.

Reliable Bubble-Tight ShutoffThis valve achieves leakage class bubble-tight, guaranteeing complete shutoff and preventing media loss. Whether controlling flow in chemical, pharmaceutical, or water treatment plants, it ensures safety and regulatory compliance with industry standards.

FAQs of PFA Lined Butterfly Valve (Wafer Type):

Q: How does the PFA lining enhance the performance of the butterfly valve in corrosive environments?

A: PFA lining provides excellent chemical resistance, protecting internal components from corrosive liquids, acids, and aggressive chemicals. This ensures longer valve lifespan and consistent operation in environments where metal valves may quickly corrode.

Q: What flange standards and connections can this valve be fitted to?

A: The valve is compatible with ANSI 150#, PN10, and PN16 flange standards. Its universal wafer-type design facilitates easy mounting between various types of flanges, making installation straightforward and versatile.

Q: When is it suitable to use this PFA Lined Butterfly Valve in the process system?

A: This valve is ideal for use in chemical processing, pharmaceuticals, petrochemicals, and water treatment facilities when handling corrosive or hazardous media and requiring reliable shutoff within a pressure range up to 10 bar and temperatures from -20C to +180C.

Q: Where is the PFA Lined Butterfly Valve commonly installed?

A: It is typically installed in industrial piping systems, process lines, and utility lines in chemical plants, pharmaceutical manufacturing, petrochemical refineries, and water treatment plants where resistance to corrosion is critical.

Q: What is the process for installing the wafer type butterfly valve?

A: Installation involves positioning the valve between two pipeline flanges, aligning bolt holes, and securing with flange bolts. The universal wafer design allows for quick, efficient mounting without special flange adaptors, reducing downtime during replacement or maintenance.

Q: Which operational options are available with this butterfly valve?

A: The valve comes with options for lever, gear, or actuator operation, enabling manual or automated control suited for diverse industrial process requirements.

Q: What are the main benefits of using a PFA lined wafer butterfly valve for industrial applications?

A: Benefits include superior corrosion resistance, reliable bubble-tight sealing, universal fit for various flange standards, extended service life, and compatibility with stringent industry design and safety standards.

Send Inquiry

Send Inquiry Send SMS

Send SMS